Wire-to-Wire Connectors and Wire-to-Board Connectors: Why Do They Break?

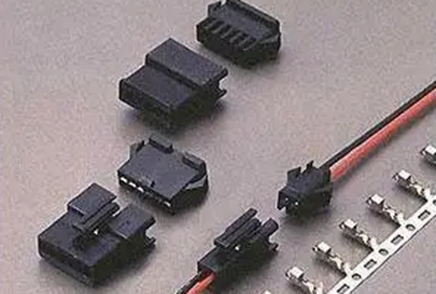

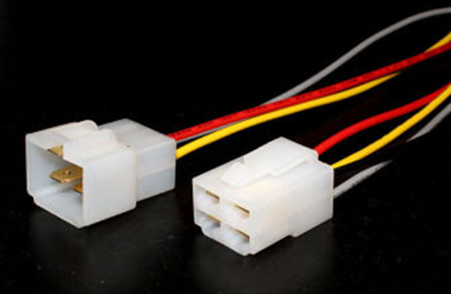

As we know, wire-to-wire and wire-to-board connectors are essential components of any electrical system. They allow for the efficient transfer of signals and power between different parts of a circuit board. However, these connectors can sometimes break, causing a variety of issues.

What are the factors that cause wire-to-wire connectors and wire-to-board connectors to break?

1.Mechanical Stress

Mechanical stress is one of the most common causes of connector failure. When connectors are subjected to excessive bending, twisting or tension, they can become damaged or even break. For example, if a wire is pulled too tightly through a connector, it can cause the connector to deform or crack. On the other hand, if a connector is twisted too much during installation, it can also become damaged.

2.Temperature Changes

Temperature changes can also cause connectors to fail. When connectors are exposed to extreme temperatures, they can become brittle or even melt. This can cause the connector to crack or deform, leading to poor performance or complete failure.

3.Corrosion

Corrosion is another common cause of connector failure. When connectors are exposed to water, chemicals, or other corrosive substances, they can become corroded. This can cause the metal contacts in the connector to corrode, leading to poor electrical performance or complete failure.

4.Vibration

Vibration is another factor that can cause connectors to fail. When connectors are subjected to repeated vibrations, they can become loose or even break. This can cause poor electrical performance or complete failure.

5.Improper Connector Selection

Improper connector selection can also lead to failure. When connectors are selected based on cost or other factors without considering the specific requirements of the application, they may not be able to withstand the stresses and strains of the system. This can cause poor performance or complete failure.