Something about Wire to Board Connectors

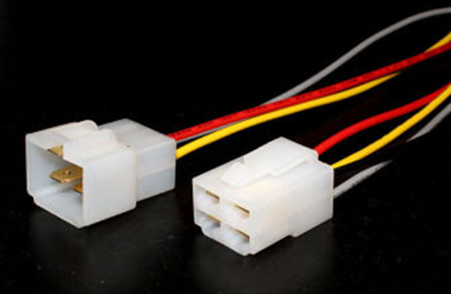

Wire-to-board connectors are an essential component in electronic devices such as automotive, appliance, industrial, data & telecommunications, consumer electronics. They are designed to connect wires to circuit boards to ensure proper functioning of electronic devices.

Wire-to-board connectors are an essential component in electronic devices such as automotive, appliance, industrial, data & telecommunications, consumer electronics. They are designed to connect wires to circuit boards to ensure proper functioning of electronic devices.

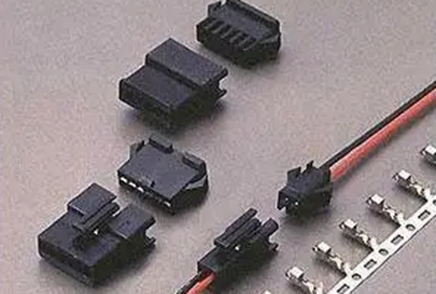

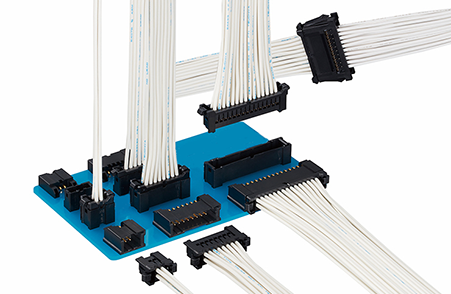

Wire-to-board connectors consist of housings, contact terminals, and wafers. The housings are made of insulating materials, while the contact terminals are typically made of metal. The wafers ensure the connectors staying securely in place.

When designing a wire-to-board connector, one of the primary considerations is the number of wires that need to be connected. The connector’s housing must be designed to accommodate the appropriate number of wires. The housing is usually molded into the required shape, and the contact terminals are inserted into it.

An important consideration in the design of wire-to-board connectors is the type of wire that will be used. The wire gauge and insulation diameter must be taken into account when designing the contact terminal. The contact terminal must also be designed to provide a secure and reliable connection to the wire.

The locking mechanism of wire-to-board connectors is also an important consideration. The mechanism must be designed to provide a secure connection between the housing and the circuit board. This ensures that the connector stays in place even if the device is subjected to vibrations or other stresses.

Durability is also an essential consideration in the design of wire-to-board connectors. Electronic devices are often exposed to harsh environments, such as high temperatures, moisture, and dust. The connector must be designed to withstand these conditions without deterioration or failure.