How wire to wire connectors are designed

Wire to wire connectors are important components in electrical systems. They are essential in connecting wires together.

Wire to wire connectors are important components in electrical systems. They are essential in connecting wires together.

Designing wire to wire connectors requires taking into account various factors such as the intended use, working environment and the type of wires that will be connected. Connectors designed for use in extreme environments such as high temperatures and humidity are made from materials such as silicone rubber to withstand harsh weather conditions.

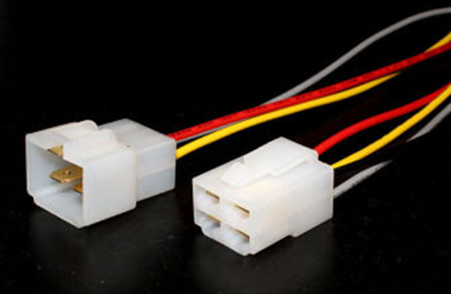

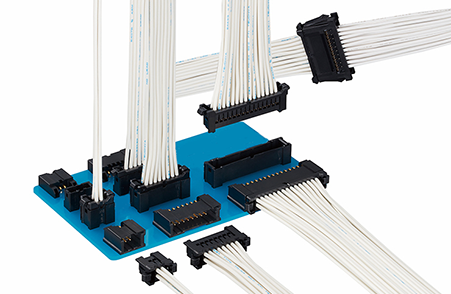

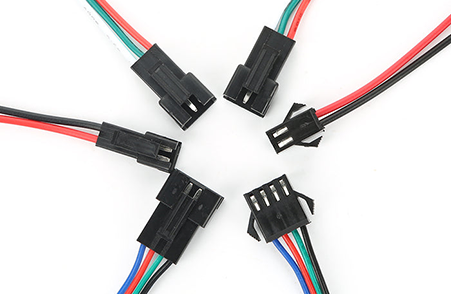

Wire to wire connectors have different shapes and sizes to fit different connections. The size of the connector is determined by the gauge of the wire that it will be used to connect. A connector designed for a small gauge wire cannot be used for a larger gauge wire, as it may cause poor connectivity and potential safety issues such as overheating and short circuits.

Connectors are designed to have contacts that are crimped onto the wire to create a strong and reliable connection. The contacts are made of materials such as copper and brass, which are excellent conductors of electricity. They are plated with metals such as gold, silver and tin to prevent oxidation and corrosion, which can reduce the conductivity of the connector over time.

Wire to wire connectors are easy to install and remove to save time and effort. They are designed with features such as locking tabs, which secure the connector in place, and release latch, which allows easy removal of the connector.

Wire to wire connectors are an essential component in electrical systems, ensuring the reliable transfer of power between components. They are designed with specific requirements in mind such as the intended use, environment, and the type of wires they will connect. Connectors come in different shapes and sizes to fit different connections, have contacts made from durable materials, and are easy to install and remove. As a result, wire to wire connectors play a critical role in ensuring the safe and reliable operation of electrical systems.